Cummins Fire Pump Drive Physical Engine Installation Guide

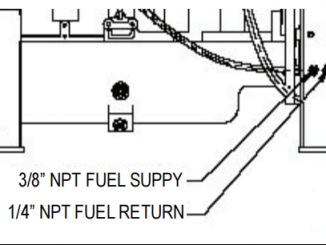

This article mainly introduces CFP83 SERIES Fire Pump Drive Physical Engine Cummins INSITE 8.7 Pro 2021 Electronic Service Diagnostic Software Installation Guide Location Refer to […]

This article mainly introduces CFP83 SERIES Fire Pump Drive Physical Engine Cummins INSITE 8.7 Pro 2021 Electronic Service Diagnostic Software Installation Guide Location Refer to […]

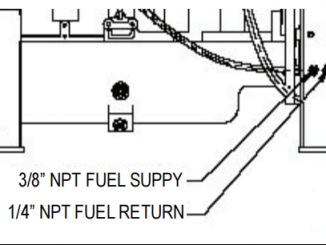

On this page we will inform You how to find out if Your Cat ET has ECM flashing possibility. 1. Hook up machine/truck/engine that You […]

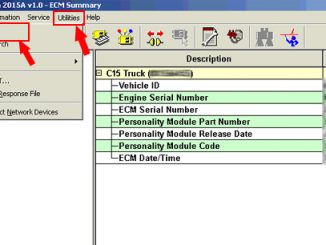

This post guide on how to update original VOCOM II 88894000 software and firmware Before update operations,you need to download the Vocom II driver. https://www.obd2tool.com/blog/2021/12/28/volvo-vocom-ptt-1-12-2-7-116-software-free-download-and-installation-video/ […]

Last Year Noregon announced its second major update for JPRO Professional Diagnostic Tool, its in-shop diagnostic and troubleshooting tool. The release, JPRO Professional 2021 v2, […]

Online Licensing for Activation the Caterpillar ET Software Licensing #Note: The contents of Licensing apply only to Dealer Coordinators. To obtain licensing information, contact the […]

Cummins VERY LATEST INLINE 7 Data Link Adapter: It’s like adding a turbocharger to Electronic Control Module downloads and uploads. Cummins new INLINE 7 Data […]

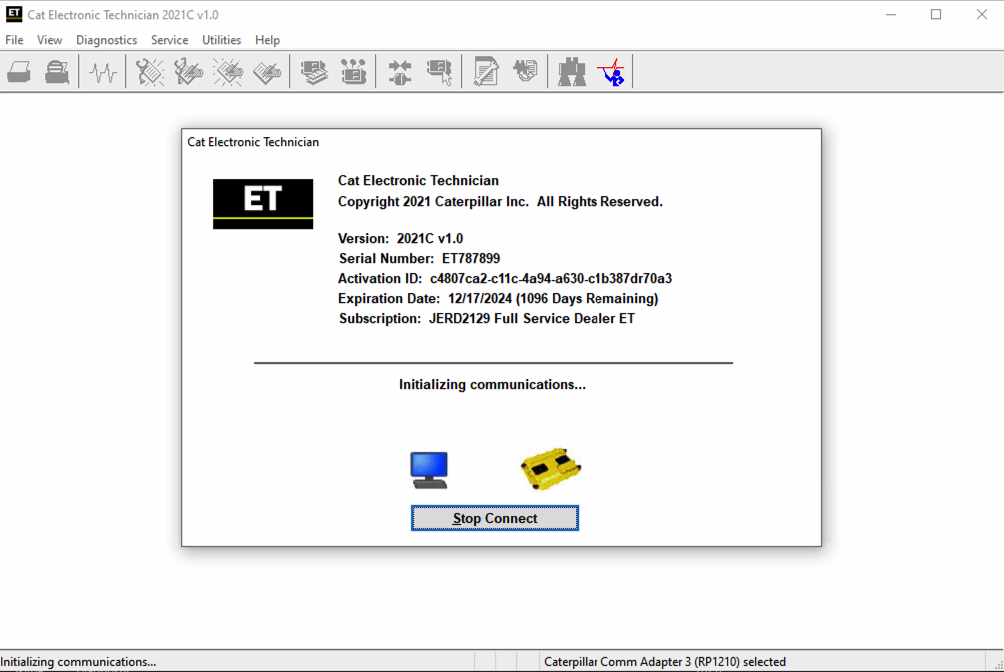

Caterpillar electronic technician 2021C(replaces CAT ET 2021B) with WinFlash future is an updated version of the caterpillar dealer diagnostic software that can help technicians to […]

John deere EDL V2 diagnostic kit with Service Advisor EDL V2 V4.2 Software, you can view service manuals, use DTAC (Technical Assistance Center) data, make […]

JCB Electronic Service Tool diagnostic interface is used for fast and effective fault finding, check maintenance standards, see if the machine has been abused, view […]

Remote Throttle 1). Use CAT ET to Check the Programming of the Parameter Dedicated PTO Parameters. →Connect CAT ET to the data link connector. →Access […]

Copyright © 2025 | WordPress Theme by MH Themes