This article mainly introduces CFP83 SERIES Fire Pump Drive Physical Engine

Cummins INSITE 8.7 Pro 2021 Electronic Service Diagnostic Software

Installation Guide

Location

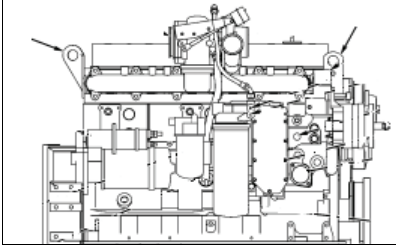

Refer to Drawing CFP83 GEN in Section 13 for the general fire pump and engine layout.

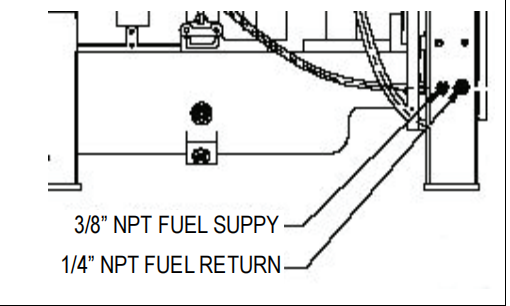

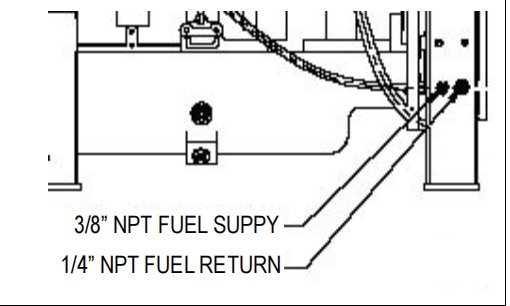

Refer to the following drawings in Section 13 for the general fire pump engine power module assembly:

WARNING Do not operate a diesel engine where there are or can be combustible vapors. These vapors can be sucked through the air intake system and cause engine acceleration and overspeeding, which can result in a fire, an explosion, and extensive property damage. Numerous safety devices are available, such as air intake shutoff devices, to minimize the risk of overspeeding in which an engine, because of application, might operate in a combustible environment (from a fuel spill or gas leak, for example).

Cummins Engine Company, Inc. does not know how you will use your engine. The equipment owner and operator, therefore, are responsible for safe operation in a hostile environment. Consult your Cummins Authorized Repair Location for further information.

Install the fire pump engine in a sheltered environment protected from extremes of weather. Any enclosure must protect the water supply from freezing. Ensure that the engine and electrical components are not exposed to significant water dripping or sprays. Avoid installation in a dusty or dirty environment. Provide adequate physical protection from other physical damage as may be present in the specific location. (Refer to National Fire Protection Association NFPA20-2003 Chapter 11 for additional installation requirements for installations in the USA.)

Design the installation to meet the engine’s mounting requirements. Refer to General Engine Data in Section o. Install the engine on a stable level foundation that is designed for the load and vibration of pump operation.

Install the engine with ample room for servicing of the engine, the pump, fuel supply, and support systems.

Ensure that the engine location is free of any risk of exposure to combustible vapors.

Cummins INLINE 6 Data Link Adapter Truck Diagnostic Tool

Physical Installation

Use the supplied lifting hooks on the engine to

position the engine.

Provide engine support as required to support

the wet weight specified in General Engine

Data in Section 10.

Position the engine as required for the interface

with the pump, piping, and electrical

connections.

Level the installation with shims as required.

Secure the engine to the support or floor.

Connect the exhaust piping

Leave a Reply